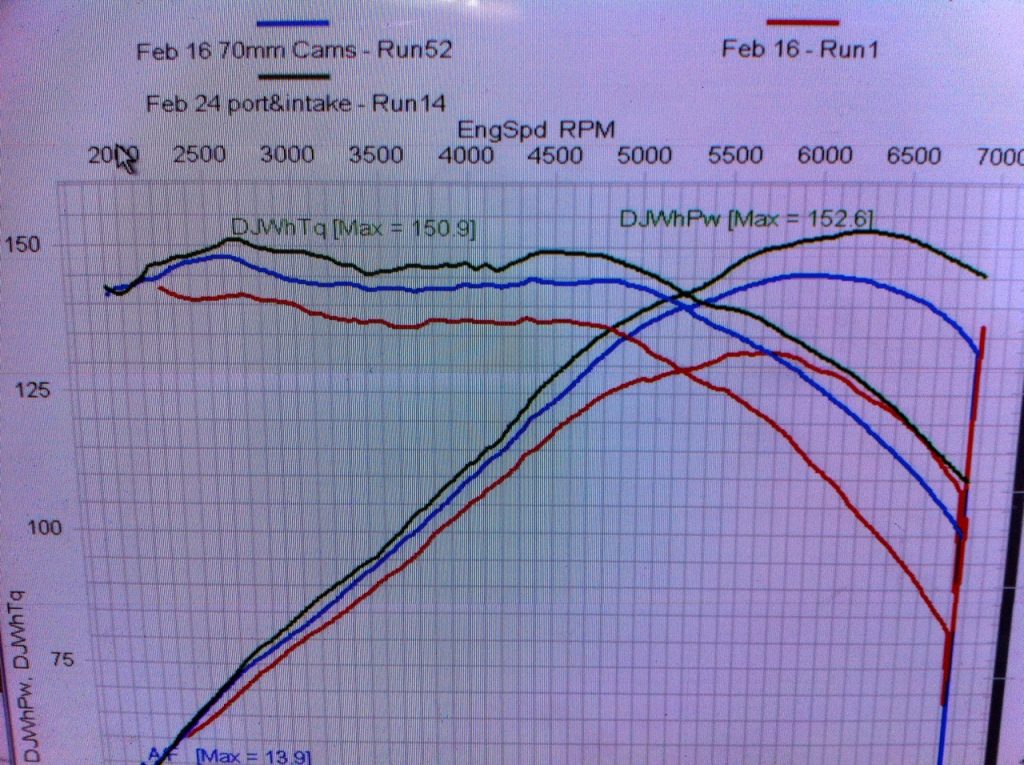

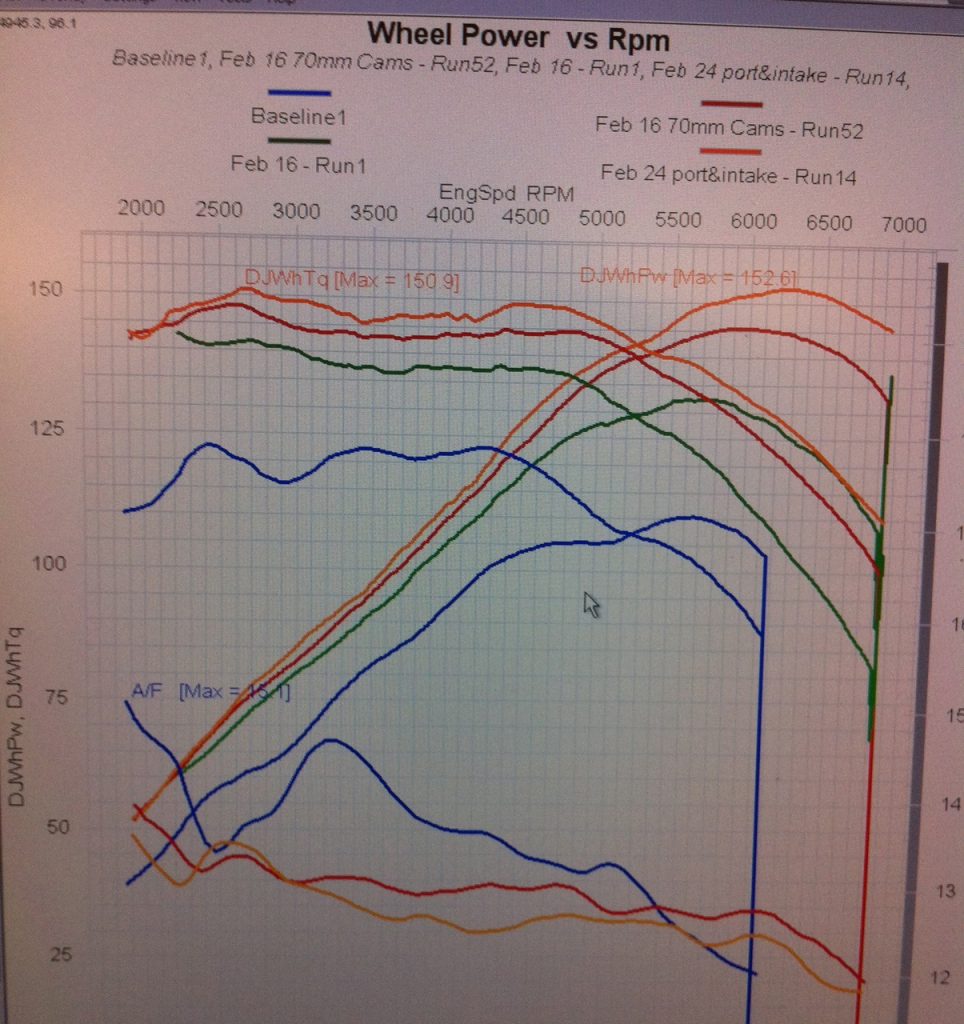

In the chase of power we started to see the need to adjust the cams changing the basic shape of the power curve. Running the Big ENEM cams from Sweden on stock gears didn’t work!

By now I had had lots of Turbo Hondas and other cars through my Dyno. nearly all had more compression and. A power than we did. It’s hard to make NA power. Can’t just up the boost. So in -06 I Picked up a 2.3i for Dyno mule duty. Ended up making more whp than the 2.0t 185. It was a beast.

The little 2.3na it’s was common to try 10 or 20 cam setting iterations in a session. Why modify the 2.3NA? A 90whp turbo without boost. Double that and see how much the extra energy wakes up that big turbo!! We did throw a 6262 and headed north of 600whp on that NA Dyno mule. This was the basis of the Red Viggen 10.25/1 setup.

Now for the How

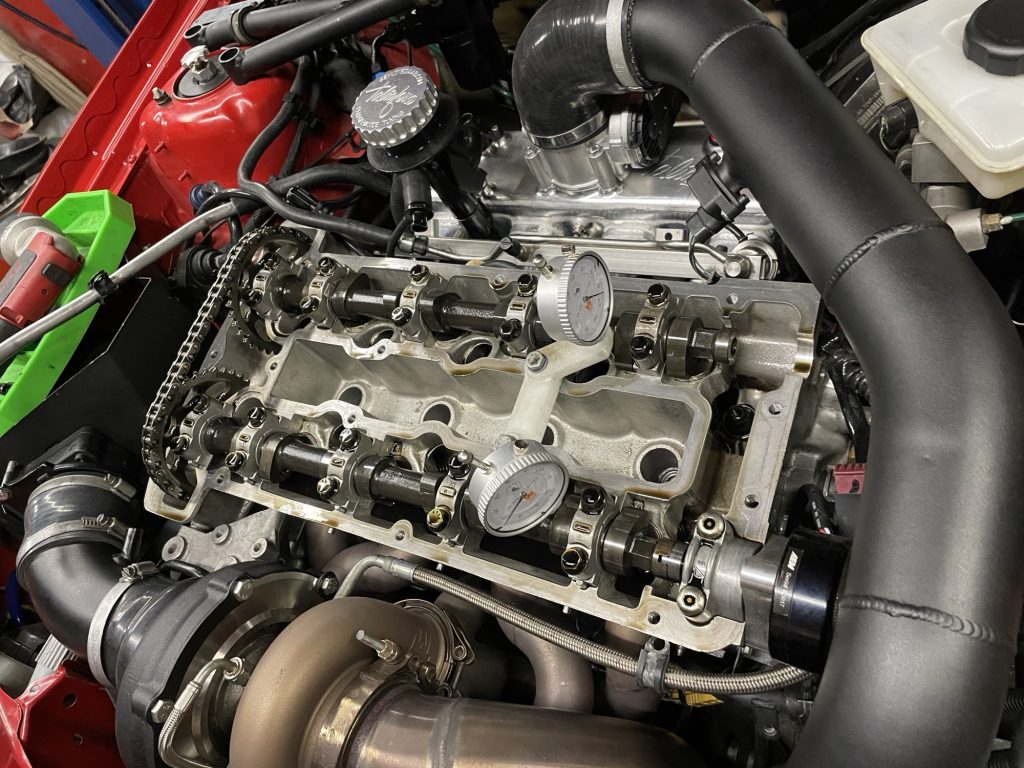

When they regrind the cams or maybe you are mixing NA cams the stock timing isn’t ideal. First I bought some adjustable gears from Sweden, they didn’t fit and were pretty rough. I set out to design and machine a better quality gear. After a couple months of that we had a working production part. The basic concept sucked! You couldn’t get to the adjuster screws.

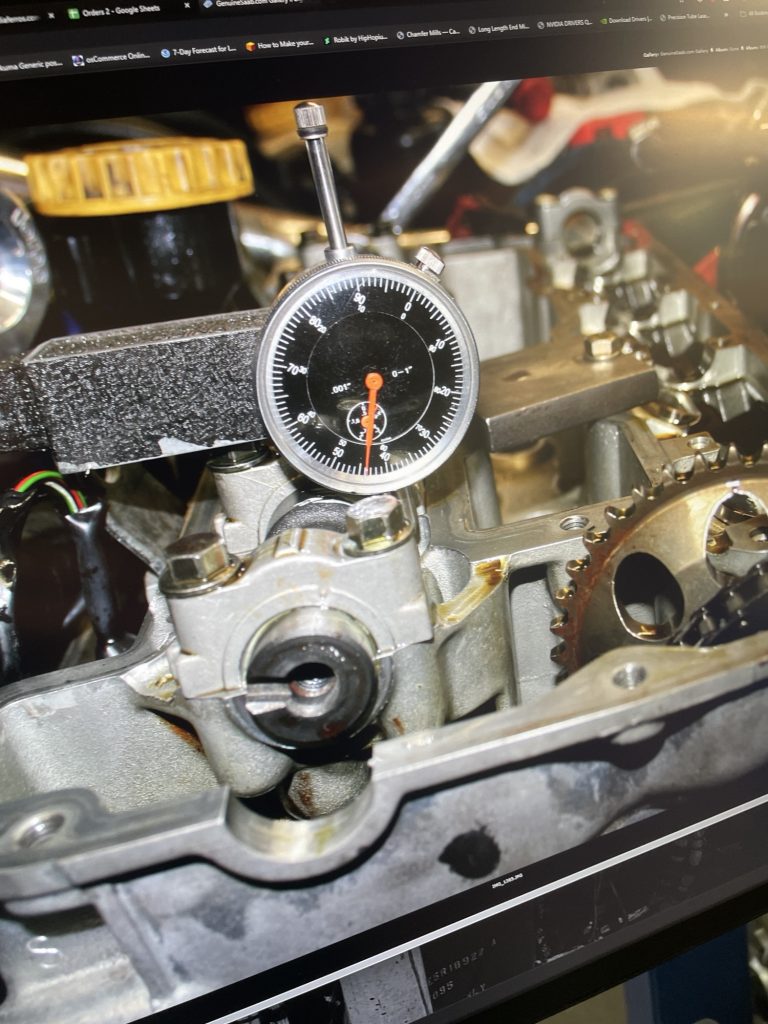

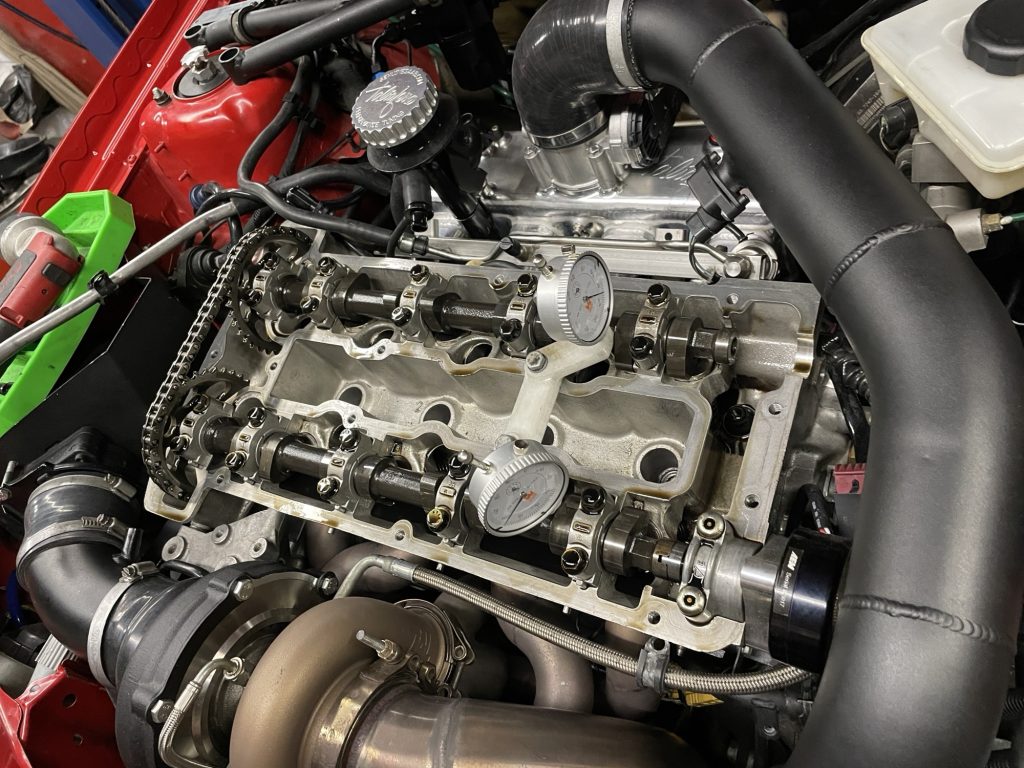

We are not adjusting the cams with Degrees. Can’t get in to the crank when it’s assembled. Instead we use Opening at Top dead center. Make sure to verify the crank timing mark is good with an indicator. Simply we pop it in 4th get and kick the Dyno roll till the cranks on.

Another friend mentioned to cut the tooth in the stock gear. Making it like the B207. This let us iterate in a few minutes on the Dyno. Adjust cams, Recalibrate fuel and MBT Ignition then make a pull. Try it all again until the gains diminish.

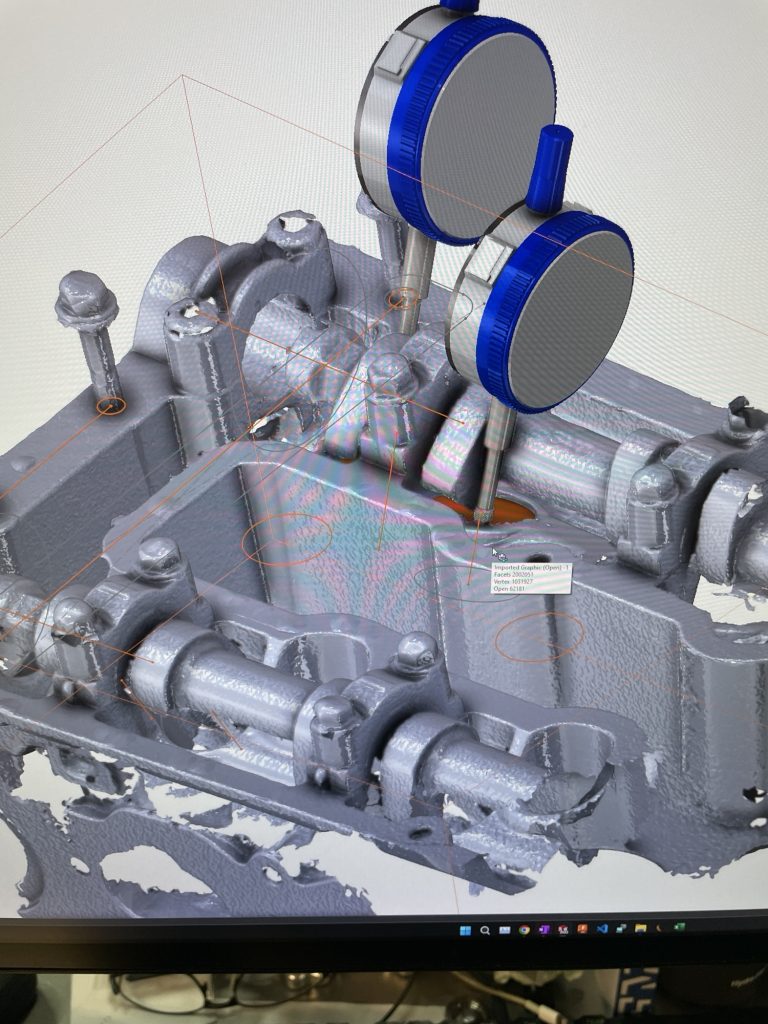

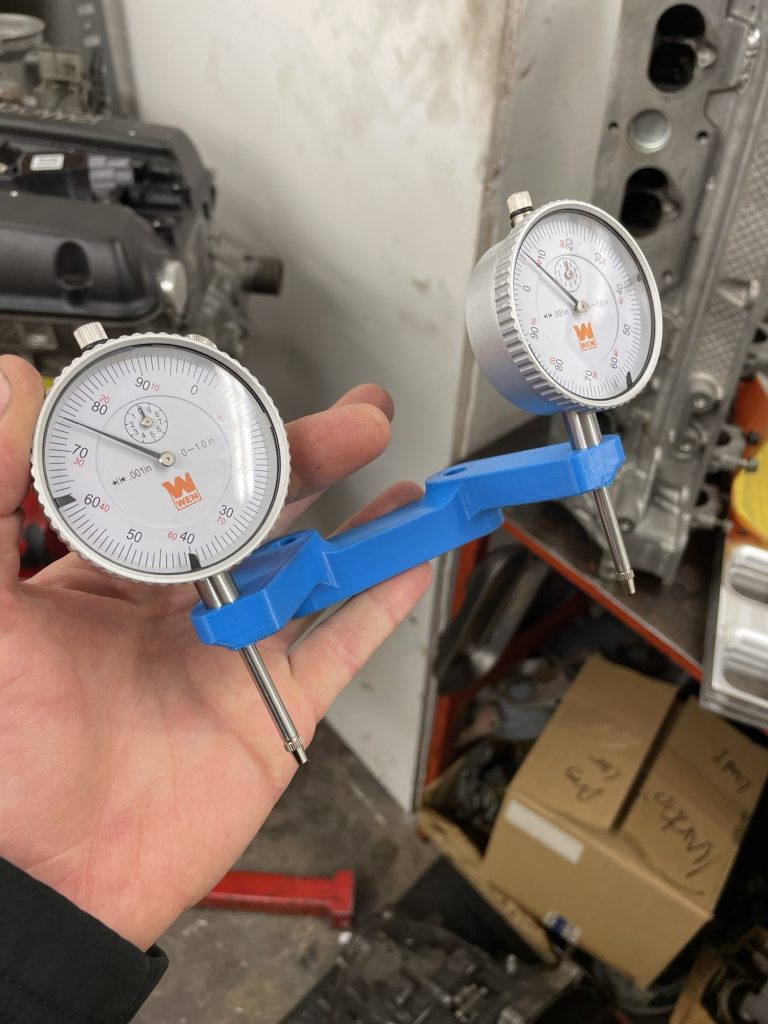

Now 10 years later I grabbed the 3d scanner. Spent a couple hours getting the indicators to fit just right. After that it was a quick model and send it to the printer.

This simple too Made it super quick to dial in the 264 cams. Now that we solved why they didn’t help years ago…. More on. That in a bit.

Mainly we found the best setup on most turbos to be T5 turbo cams. They were all the same. 9000,900 etc. B204 B234. Once you get a big enough turbo ( with low enough turbine restriction) then we could add some Duration and lift to the exhaust. Gt3071.64 etc. On a t7 setup it’s not the intake cam making the problem ..

If you read this far and need one or tips on what setting to start with just reach out. If there’s enough demand I’ll make a YouTube video of this.

Here’s a video on the gears I can’t seem to embed.

https://www.instagram.com/p/C80WXrEuJyd/?igsh=NWRhaHFrdjMyY2xv

-Nick Taliaferro