|

[427×640] [800×1200]

Somethings Missing

|

[640×427] [1200×800]

Oh there it is in the oil pan…

|

Drag Car Adventures

Favorite book this week.

Advanced vehicle technology by Heinz Heisler and his Advanced engine tech books are certainly worth a read for anyone in the industry. 500 pages of tech is too much for some, just right for me. 🙂 Best part is the inter-library loan so you can preview the book before plopping down a c-note.. You can look through it on Scribd.com

Advanced vehicle technology by Heinz Heisler and his Advanced engine tech books are certainly worth a read for anyone in the industry. 500 pages of tech is too much for some, just right for me. 🙂 Best part is the inter-library loan so you can preview the book before plopping down a c-note.. You can look through it on Scribd.com

Custom Pedals Installed

Got my pedals installed. They are the same production parts but had to make them a bit special. First step was powder coating them in the texture black. (as with everything else possible under the hood. 😉 The cool part was attacking them with the belt sander to bring out the pattern. Only cost me a couple fingertips. They felt great with my shoes on the way home.

When Good Urethane Goes sour…

Trying to get a nice golden yellow color for one of our urethane compounds we found we could only make Slime/Snot color. Its not your screen.. Really that ugly. Think we will pass on that for now.

Viggen Flys again.

Runs again on the Gt2871. Just putting miles on it with baseboost and under 4500rpm. . Even there it feels quick. The new brakes are very impressive! The pedal feel as expected is a touch grabby. Might need to swap to a std 9-3 booster/master cyl. If only the 245s from my Aero would fit on this car. As soon as we get a 10.999 with the 2.0L Gt3071 that turbo will come back to the viggen and the new target will be made.

More Viggen Parts

Powdercoated the intake manifold. It started just smoothing the sharp casting flaws but then turned into cleaning up the ports etc. Did it in the texture black. Should have it all bolted together tonight and latest tomorrow.

While there smoothed the throttle body with the die-grinder, both inlet and outlet. Should help a bit with max airflow. There were pretty poor steps from the factory. The throttle body heat was also shaved from the waterlines.

Machined some custom Pedals

I wanted some custom pedals for my car that didn’t add much thickness and were very grippy. Couple revisions and I think we nailed it. In the Spirit of the Viggen and not meant to be a direct copy etc.. Best part is I had a price in my mind and it turned out to be half what the other guys charge! Also the first product to display the new GS logo that we introduced as SOC 09 sponsor. (Final parts are curved to match the pedals.)

Inner Swaybar Bushings…

This is why we don’t make or sell an inner sway-bar to subframe bushing for the NG900/9-3. Stock is a quite hard 87 durometer with those purple bushings from the UK actually being softer than stock.. Not really an upgrade right. 😉 Maybe a valid replacement part. The stock will do just fine for my cars. So please quit sending emails and asking. 🙂

Home garage engine install…

So the last couple nights I have been putting the newly built engine and gearbox in my viggen at home with basic tools. Borrowed engine support beam from the shop and grabbed my 1/2in torque wrench for the big bolts. Rest are my basic kit from sears. Bit of a contrast to my full snapon box at work. (that I barely get to use anymore) it’s refreshing to be able to work straight for a couple hours with no interuptions.

Monday night I hoisted the engine into place with a climbing rope straddling the engine bay. My buddy bolted up the engine mount as I held it. Not the lightest motors these b235s.

Tuesday threw up the gearbox. Jack wouldnt reach so had to manually lift and hold it. My limit on one arm military press is about the gearboxes 150lb using the othe hand to start the bolts 🙂 got all the accessories installed. Forgot a rear mount so called it a night.

Getting a hand tonight w the subframe tonight. Should be running this weekend. Sad to say but the 2.3i feels fast to me compared to the truck. Will have all the build details up soon. Home now with the AT&T guy so I should finaly have Internet and splurged on HD uverse. 🙂

Viggen Motor

Spent Sunday over at the worksop to get My motor together. Still need to throw together a gearbox but making headway at least.

I was putting off timing the cams since the old way with the cut gears was a total pain. My new gears sure are slick. Took maybe 20 min to do the whole topend!

Will have a post on camshaft timing soon.

Swapping Brakes

Filed under: (Nicks) Viggen, Chassis, NG900 Project Car

Wanting to take the red -94 project car to the strip with it’s new mods to see how it goes I had to swap brakes. The slicks are 15″ and require the 288mm or smaller brakes. I pulled the base 9-3 brakes off the Viggen along with the hawk HPS This left me with the like new 330mm AP racing brakes to replace my used up WP 336s that were on Viggen.

The AP on the NG900 with the stock tiny rear brakes and std booster stopped very well. If anything they were over sensitive and were a bit hard to modulate on the street tires. The Vig still on the 300mm rears with the hawk track pads and the 288s stopped surprisingly ok. Now it should stop very well, if not too aggressive.

With the lip on the Bordet wheels it took a 6mm spacer to get them to clear and that only made the fender rubbing in the front worse. As expected it is better with the spacer out. The BBS CH clear the AP with lots to spare thankfully.

Only major issue I found during this was the front lines on the AP were dangerously short. Tight with maybe 80% turning! So I have to get Goodridge to make some custom lines. The lines from My vig were plenty long even with my steering mod. More on that last part later. 😉

The reds sure clash…

Little present for my E85 SS

Replaced the Aero logo on the trunk with a factory BioPower logo. Good for at least 5rhp (rice horsepower) Used a 3m eraser wheel and then a little polish to clean up the ghost marks. It was about time too since it has been eating corn for over two years. Even washed it!

Ng900 suspension mods

Started the first round of suspension upgrades on the -94 red project. Drove it enough before to get a good baseline for the mods before this. The main issues I had with it were the front being much harder than the rear gave it a very mushy feeling, leaning back under any acceleration and fighting for forward grip in the corners.

The car came with Abbot rear springs, Koni Sports and hard coilovers in the front. Sway bar is a Yellow code stock and the rear is an abbott. Front stuts were modified for

The first change was stiffening up the rears with a hair softer spring that I run in the 400hp+ cars. Also knowing this was not a drag car and would mostly see street use that fits. This has proven on my other builds to work great and did not disappoint. The best improvement is during acceleration the car does not lean back and unload the fronts. Here is a video with some before and after.

While I was swapping the brakes around It was time to do the quick steering modification also. Dropped the uprights out and the guys here at the shop whipped them out in about 1 hour. I went a little more mild than the 2.3i since this turbo has the bit faster rack already and will be used for higher speeds than the poor N/A. Afterwards I had it aligned and have not been 100% happy with the setting. May have to dig into that down the road.

While I was swapping the brakes around It was time to do the quick steering modification also. Dropped the uprights out and the guys here at the shop whipped them out in about 1 hour. I went a little more mild than the 2.3i since this turbo has the bit faster rack already and will be used for higher speeds than the poor N/A. Afterwards I had it aligned and have not been 100% happy with the setting. May have to dig into that down the road.

We still have to figure some sort of strut bar. The stock was removed when the previous owner modified the strut towers for camber adjustment. We did put a black 6-point on it to help the chassis. Needs a rear hatch brace with the stiffer springs. They sure accentuate the chassis flex when you stiffen up the suspension.

Ng900 Project car “Red” hits the dyno

Today was the first day for the NG900 Project car on the dyno. I added a APC valve and a basic stg4 tune for the 15t5cm last week. I have never been a fan of the MBC. Overshoot in 2nd and not enough in second, well till it cooled off.. Suddenly with some reasonable boost management by gear we have 1 bar in 1st, 1.4 in second and 1.5 in the rest the racelogic wasn’t so important to have. This car has the 6cm 9k hot side. I know 18t right 🙂 Just wanted to get some runs on a basic tune so it is more fun on the road while I sort the chassis. Turned into a little more than that. Here is the HD Video from today. Read the rest of this entry »

Today was the first day for the NG900 Project car on the dyno. I added a APC valve and a basic stg4 tune for the 15t5cm last week. I have never been a fan of the MBC. Overshoot in 2nd and not enough in second, well till it cooled off.. Suddenly with some reasonable boost management by gear we have 1 bar in 1st, 1.4 in second and 1.5 in the rest the racelogic wasn’t so important to have. This car has the 6cm 9k hot side. I know 18t right 🙂 Just wanted to get some runs on a basic tune so it is more fun on the road while I sort the chassis. Turned into a little more than that. Here is the HD Video from today. Read the rest of this entry »

New sport rear mount for NG900/9-3

Filed under: (Dark) Viggen, CNC / R&D Parts, NG900 Project Car, Powertrain

With a few of these out in the wild and more headed that way, time for a place to keep all the info together.

With a few of these out in the wild and more headed that way, time for a place to keep all the info together.

I have one in my new -94 900 Project car. Along with just sport trans mount, tdo4 etc. Feels great. Little more vibration if I bog it off idle but thats about all. Makes the shifter solid! Here is a video playing on the way to work. You tube HD video link That was driving it quite hard and the shifter stays put. 🙂

The black viggen has one too. Looking forward to his input.

Also the original prototype is still in the 2.3i beater car. I love the way that car responds. Post Link

Also the original prototype is still in the 2.3i beater car. I love the way that car responds. Post Link

Show to the right is just some of the testing we did for the new mounts. You can even see the dead stock one that we blewup. All variants were tested including a Diesel. It was important that we keep the loaded heights the same while limiting travel.

New blended Header flanges for the B2x4 and B2x5 Motors

With the last batch of header spacers we also ran some 3d ported flanges for manifold construction. Designed for 1-1/4 sch10 pipe. They are opened up to the gasket size so it would be wise to port the head a little. Should have them for sale on a custom basis if anybody needs one. Should be nicer than smashing the tubes to match the ports.

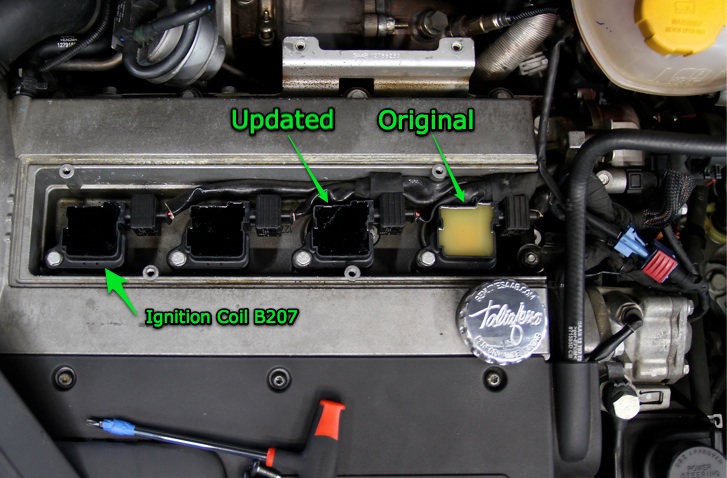

9-3SS Ignition Misfire when tuned

Identifying the 4cyl Coils to fix the misfire on stg3 up. This is like a dead hole on full throttle.

If running the Plug gap a little closed down helps then you need new coils. (Close would be .8mm) Ngk BCPR7ES-11 A cheap factory Copper plug, Inspect every 20K miles.

When we turned up the 2.0T above stg1 we run into this and decided it would be helpful to the rest out there to identify the old coils.

The early white coils seem to misfire above stg1 on the B207R (210hp)

The plug cover comes off with the screwdriver in the trunk. 30torx. You need a 10mm socket to pull the coils and a 5/8″ sparkplug socket.

Catalog link: Ignition Coil 9-3SS 2.0t and 2.0T More info on the selecting the Right plugs?

Cam Gears

UPDATE Mar 17 They are done.

—————

Been working with Steve to get the cam gears finished along with everything else. Started the project nearly 5 years ago. Found a supplier that could machine us custom gears of 4140 alloy steel. Best part is that they are heat treated to the same spec as factory gears for lifetime durability. Added a 27mm hex to the nose making it easier to torque the cam bolt and adjust the timing. Production parts and setup video to follow. Still a couple weeks out on the sprockets. Here is an early model. Not final but you get the idea. Hopefully there is enough interest to keep the price down.

Updates

Black Viggen Is on the dyno. Just starting to open it up. Video On Youtube VigDark Dyno

NG900 Project car; We are still fighting the clutch. But not spending much time on it. Trying to get the rest of the projects done.

New rear motor mount prototype parts were picked up from the waterjet contractor. Still waiting on fasteners so those should be welded up early next week. The raw parts looked neat so heres a pic. Also some new round pointy things coming out of R&D they have 38 teeth and 4140 alloy steel is the material. 😉

New Project Car Arrives…

DIRTY! More updates as the plan is formulated. We have to swap the clutch as a first step to get it going. After that with some fresh 94 octane gas we can baseline dyno it and go from there. Should have some parts for sale that will help support the drag car this year.

Mounts and Steering

Putting some miles on the 2.3i car to test both the new steering mods and the prototype rear mount. Shown here is an early version.. just dirty to test the design. We are at r4 or r5 now and real close to production. That we have reached this point on the 2.3 with no balance shafts and a harder than production trans mount is nice. Now I need a few people willing to beta test them once we get some more made up. You will have to report back to me. Also you must be willing to swap the mount possibly more than once. At least a stg3 car with my trans mount too. Leave a message in the comments or email me: nick at this site. This mount is not aimed at the Full race but more your everyday sportscar needing more than the stock rear mount. But not as far as our full race mount that would be too rough for a daily driver.

Putting some miles on the 2.3i car to test both the new steering mods and the prototype rear mount. Shown here is an early version.. just dirty to test the design. We are at r4 or r5 now and real close to production. That we have reached this point on the 2.3 with no balance shafts and a harder than production trans mount is nice. Now I need a few people willing to beta test them once we get some more made up. You will have to report back to me. Also you must be willing to swap the mount possibly more than once. At least a stg3 car with my trans mount too. Leave a message in the comments or email me: nick at this site. This mount is not aimed at the Full race but more your everyday sportscar needing more than the stock rear mount. But not as far as our full race mount that would be too rough for a daily driver.

The steering modifications are quite ok on the street. We might need to put just a touch more toe in it like stock or replace the bushings with poly. Certainly doing this to my Viggen next. Maybe not so aggressive of a change but it makes the car feel quite unlike any NG900/9-3 I have driven. I was thinking with the rest of the mods it should make quite a package. -N

Tuning…

Not sure many out there fully understand what is involved in proper tuning.. Not just the “turn maps up” kind and a quick run on a dyno to get some numbers. If you are lucky they monitored A/F and thats about it.. EGT? nope, Most dynos don’t have enough fan to get near cooling a NA car much less simulating the airflow needed to cool a turbo car. Inertia only you can’t simulate rear world acceleration rates. Did they actually find ideal timing and A/F ratios for this setup? Real tuning takes lots of time on the dyno to get the best for the customer.. The hourly cost of at least $60/hr for a dyno is cheap. We have invested over $50k in the dyno cell alone. My belief here is that by spending for unlimited time upfront we can not be rushed to make the clock. Then it is not the best to “try” on customer cars. So the Business has to invest in development vehicles. Then these cars go to the racetrack and street for long term testing. It is easy to see those that are actually developing and those that are simply copy/paste… Unfortunately just like the china parts usually the copy is pretty good. Looks the same to the short sighted customer. Is it right? Sure shows on the racetrack though. 🙂 Over the years I have witnessed all sorts of tuners on the dyno. Just like anything lots of different methods with varying degrees of success.

Not sure many out there fully understand what is involved in proper tuning.. Not just the “turn maps up” kind and a quick run on a dyno to get some numbers. If you are lucky they monitored A/F and thats about it.. EGT? nope, Most dynos don’t have enough fan to get near cooling a NA car much less simulating the airflow needed to cool a turbo car. Inertia only you can’t simulate rear world acceleration rates. Did they actually find ideal timing and A/F ratios for this setup? Real tuning takes lots of time on the dyno to get the best for the customer.. The hourly cost of at least $60/hr for a dyno is cheap. We have invested over $50k in the dyno cell alone. My belief here is that by spending for unlimited time upfront we can not be rushed to make the clock. Then it is not the best to “try” on customer cars. So the Business has to invest in development vehicles. Then these cars go to the racetrack and street for long term testing. It is easy to see those that are actually developing and those that are simply copy/paste… Unfortunately just like the china parts usually the copy is pretty good. Looks the same to the short sighted customer. Is it right? Sure shows on the racetrack though. 🙂 Over the years I have witnessed all sorts of tuners on the dyno. Just like anything lots of different methods with varying degrees of success.

I recently found this set of articles that takes lots of education and condenses it down to what the everyday driver can understand. Articles From Bilsport/Rototest I encourage everyone to read this that is going to tune their Saab. Maybe you will look a little deeper into the “Development” involved.

If you need a little more then Society Of Automotive Engineers (SAE) Has a good seminar. Lots cheaper now too! Was interesting to see the mathematical side of the motor after learning mostly by the A>B>A testing methods..

Comments? NickT

Customer Viggen (Dark)

Well we are almost finished on this project. Rather take a little longer that put out the junk that comes from… Anyway, plan was to make it cleaner than mine! I know right 😉 Had it out making noise today. Still missing some parts (Strut brace in custom texture black) and needs that blue plastic removed but you get the idea. More pics on the image link.

My FlipVideo died so only old camera VIDEO. Thats the exhaust in race mode with the straight pipe on the back. 1min vband swap to quiet. More videos once we get some miles on the motor and turn it up mapping it on the dyno.