Since the new “norm” for our cars is in the 400whp range the stock brakes are just not enough for most driving styles. Increasing the front capacity is the best method. My biggest gripe with the aftermarket big brake kits is wheel clearance with the fat calipers. I have a couple big brake cars that only one set of my many wheels will fit. Working around this we have some solutions to get more than enough braking in a reasonably priced package. I am not talking the taiwan/ china junk Plenty of experience with that, the WP kit is in the corner of the dyno room with ~6K miles on it. Too scared of the quality to give them away. 🙁 I want a top quality part that i can have 100% confidence in every time be it going to the store or running 150mph+ on the back straight into a 2nd gear corner. Anybody interested in them leave a note here.

Since the new “norm” for our cars is in the 400whp range the stock brakes are just not enough for most driving styles. Increasing the front capacity is the best method. My biggest gripe with the aftermarket big brake kits is wheel clearance with the fat calipers. I have a couple big brake cars that only one set of my many wheels will fit. Working around this we have some solutions to get more than enough braking in a reasonably priced package. I am not talking the taiwan/ china junk Plenty of experience with that, the WP kit is in the corner of the dyno room with ~6K miles on it. Too scared of the quality to give them away. 🙁 I want a top quality part that i can have 100% confidence in every time be it going to the store or running 150mph+ on the back straight into a 2nd gear corner. Anybody interested in them leave a note here.

+1 Brake Kit for 900/9-3/9-5 Feedback needed

9-3 SS Getting a new manifold

This was on Steves CAD desk yesterday. Should be cut from 1/2 Steel and ready for Adam to start fabbing the manifold this week. Makes quick work having the original prints from GM so we are 100% right without the reverse engineering tolerance issues.

This was on Steves CAD desk yesterday. Should be cut from 1/2 Steel and ready for Adam to start fabbing the manifold this week. Makes quick work having the original prints from GM so we are 100% right without the reverse engineering tolerance issues.

The B207R is getting at least a Gt30 it fits easily, Might get crazy and throw the 3076 or something like that on it. Have to see how wild it gets. Spare block is coming from GOLDWING Will get JE pistons and probably some mild cams/ other head work to turn some revs. This 440 has all the suspension and trans upgrades to handle some fun power. When you get out of 700hp and back in the 320hp its just not enough.. Even though 320hp is a decent amount..

-Nick T

Drag car meet Roadrace slicks.

With the long weekend I got another gearbox built. Quiafe F35 lsd, 4.45 final, short5th gear and a few other tricks.

Put my roadrace slicks on it and headed out. It was only 95 air temp. 😉 This chassis setup surely does not like the stiff wall slicks. It is not “right” at full power. Feels just like a stock viggen wallow but at a much higher frequency. I left the gopro at the shop and holding the iphone was not working too well. It was all I could do to keep it out of the dirt trying to sneak up on full power. Either way ~75miles and no problems with the gearbox or the motor even with the record heat. The car is surprisingly drivable considering it is 700whp in a 2500lb shell.

Digging into the steering rack as the next project. Pretty sure all of the problems are based there.

A new gearbox failure mode

The dragcar gearbox had an interesting failure on the last outing. Manifested as partially blocked third gear. Initially what I thought was the snap-ring that holds 3rd turned out to be the 3/4 Hub on the input shaft. The corners of it have fractured off. The bummer here is that even the magical Quaife kit does not address this. Not much initial damage here but the bits ended up in all the wrong places. 🙁

Has anyone out there experienced a failure like this? Possibly a fatigue failure from some harmonic (9k rpm and solid clutch disk) or a mechanical overload. I figured it would have killed the 1/2 since the loads there are much higher on slicks. This box did shear a handful of axles. Next step is the material science lab and look deeper into the material properties on the variations over the years to hopefully find a tougher one.

Viggen Low race springs.

Some lower race hard rear springs for the Viggen. These are the “N2L” options springs. In the catalog Now I can drop the front back down. Tires are 225/40-18s This is with full gas, 12″ sub box and co2 tank. One of these weekends I can finish my new BBS center caps. Still can’t decide to keep the hatch spoiler or go back to stock.

Some recent out-of-town cars

Some recent cars that were a ways from home out here for upgrades.

Stage 1 Nordic and strut brace on this Sweet XWD 9-3x from New Jersey. Under 10K miles too.

Stage 1 Nordic and strut brace on this Sweet XWD 9-3x from New Jersey. Under 10K miles too.

Had to put loaner wheels on this one from New York to replace his studded snows so I could custom tune it on the dyno! Even let him run it around on my tires with the new power. That was a first. haha.

Had to put loaner wheels on this one from New York to replace his studded snows so I could custom tune it on the dyno! Even let him run it around on my tires with the new power. That was a first. haha.

Local M3 in for Suspension setup. Including corner weighing. This was a local customer but fit into this category.

Local M3 in for Suspension setup. Including corner weighing. This was a local customer but fit into this category.

This one from Arizona we tuned with Nordic. The owner said it was GRRReat.

This one from Arizona we tuned with Nordic. The owner said it was GRRReat.

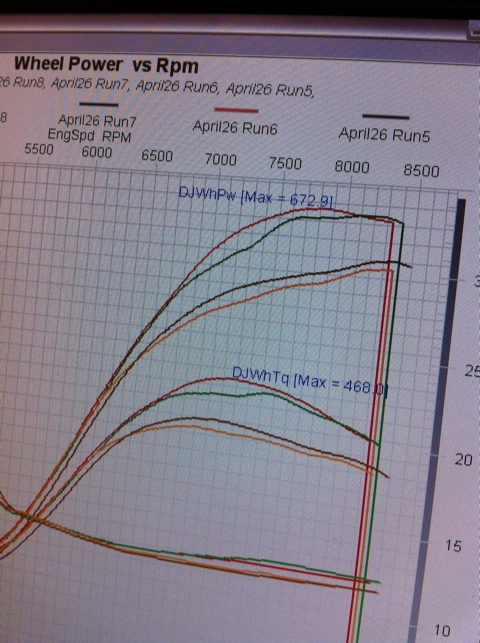

Drag car spins the rollers for 2011.. Finally

Update: Swapped the rear Walbro 255 feed pump for a Aeromotive 340 after finding the main -44 was seeing suction at max flow. With the added fueling it allowed us to make a bit more power safely. 😉 Still this is about 3/4 of target boost! No need for more now. Will have plenty, just need to sort the cage and swap an axle before test and tune Friday.. Then maybe off to KCIR Sunday for the IFO race. PS not to give it away but that peak um, plateau is 700whp.

So this new 6262 is pretty mean. Spent the afternoon getting the staged 630/1000 injectors sorted. Nira is a bit crude in that respect. Starts and idles on the 630s then at3k brings in the secondary. All works. Need some more sorting on the spoolup side. Nice power for just the wastegate spring. 😉 Looks like the fuel supply is lacking somewhere. Upper 80% already. With 4bar base we are over 1800cc/cyl. Have to address that before throwing more boost in up top. Won’t go over the current peak torque though. The underdrive alt pulley cured the electrical and belt gremlins.

It sounds mean! B205 Drag car with 6262 initial pulls Youtube Video

Now this is still a stock t5 head and manifold. Just clearanced for the cams. Man has ports added for the secondaries mounted at the top of the runners. Hoping our gains from the mild intake and big ports proven on my N/A project.

Eds 2.3 Talladega Dyno

Filed under: Customer Projects, Dyno, Eds 2.3L Talladega

Last week Ed brought up his 2.3L 90o Talladega for some fine tuning. The mail tune I sent him for the 2.3 need a bit of help, it made decent power and ok mileage though. Plus we found as always a handfull of interesting issues needing addressed before sorting the soft. Front and Rear O2s swapped lead to interesting adaption and faults. 😉 Boost control valve stuck in BOOST not base boost. I haven’t seen that before.

Last week Ed brought up his 2.3L 90o Talladega for some fine tuning. The mail tune I sent him for the 2.3 need a bit of help, it made decent power and ok mileage though. Plus we found as always a handfull of interesting issues needing addressed before sorting the soft. Front and Rear O2s swapped lead to interesting adaption and faults. 😉 Boost control valve stuck in BOOST not base boost. I haven’t seen that before.

Mainly it involved sorting the fuel, mapping all the vacuum cells with the eddy current load of the dyno. Makes it very quick, compared to fiddling about on the road for hours. Picked up a cheap 20″ LCD and mounted it on the dyno lift arm. Adjustable so it is right outside the window, Needed that 5 years ago. The dyno is controlled by a handheld box by the driver.

Mainly it involved sorting the fuel, mapping all the vacuum cells with the eddy current load of the dyno. Makes it very quick, compared to fiddling about on the road for hours. Picked up a cheap 20″ LCD and mounted it on the dyno lift arm. Adjustable so it is right outside the window, Needed that 5 years ago. The dyno is controlled by a handheld box by the driver.

The hardware is pretty common. Tubular Exh manifold, 18T 6cm, B234Swap, VIggen muffler, No resonator, 3in Downpipe and we made a custom intake pipe and wrapped it. The old SP manifold was a bit close to the pump leaving little room for the intake pipe. He has 308fronts, 300 rears and sticky tires on the powder coated fondmetals.

We ened up with the torque lower ~325 than when it arrive but made another 10whp up top with still a conservative tune. This keeps the Viggen clutch happy and lets you drive it full throttle with only a bit of spin in 2nd. This is a drive it to the trackday and on the way home pickup the grandson and groceries. 😉 It also got a Quaife LSD in the F25 and along with the usual upgrades while I was in there a taller 5th gear to drop his cruise rpms for the highway trips. There are more photos in the Album.

Underdrive alternator pulley

Machined this yesterday evening for the drag car. Had to grind a custom tool for the belt profile. The motivation for this is not more power but to slow the alternator down. Since we experienced belt issues with the stock alternator over 7500rpm accompanied by electrical glitches sometimes resulting in nira shutting off! This persisted even after swapping to a 90amp and deleting P/S. It was an Alt overspeed problem too. Since the new rev limit is closer to 9k I just changed the pulley in that percentage. Most likely would not work on the street with AC etc. Im hoping the belt stays happy for now. Probably a little on the sturdy side. Rather it be a couple grams heavy and not ever be an issue.

Machined this yesterday evening for the drag car. Had to grind a custom tool for the belt profile. The motivation for this is not more power but to slow the alternator down. Since we experienced belt issues with the stock alternator over 7500rpm accompanied by electrical glitches sometimes resulting in nira shutting off! This persisted even after swapping to a 90amp and deleting P/S. It was an Alt overspeed problem too. Since the new rev limit is closer to 9k I just changed the pulley in that percentage. Most likely would not work on the street with AC etc. Im hoping the belt stays happy for now. Probably a little on the sturdy side. Rather it be a couple grams heavy and not ever be an issue.

We also have been very busy in the CNC shop. These custom drag wheel center caps steve did last week came out really neat.

We also have been very busy in the CNC shop. These custom drag wheel center caps steve did last week came out really neat.

Alcantara Steering Wheel

Needing to replace my “long term, temporary loaned” carbon wheel… This is what I have come up with. Stock wheel slightly fatter with red stiching securing the black alcantara. Depending on how it feels We may do a group buy on these and get the price down a bit also. More Pics

Project car news

The Non turbo NG900 is waiting with a dead gearbox. The stock Diff gave up behind the slicks at the dragstrip. So much for a NA 1/4 mile record.

9-3SS with the new clutch and LSD is going great! With the added traction along with the 245 Tires it can use the midrange torque and grunt without spinning the tires (as bad). Best part is that going back to the factory style dual mass flywheel has taken away all the noise of the F40. The clutch capacity is better than the SPEC stg2+ Amazing considering this is an organic disk in it now. Even mom can drive it. The best part is the clutch always engages the same. Unlike with the Spec and its random engagement as a failed implementation of the self adjusting pressure plate.

Viggen is getting the CNC head and new manifold but thats quickly turing into a bigger project. Found the exhaust valves hitting. So the cheap solution is to grab a used T5 head off the shelf to modify and throw a cheap set of my springs in it. Should let us safely rev past 8K now running to 7500. But a t5 head has some metal missing that we need, Adam grabbed the TIG and took care of that though. The manifold is also getting tapered runners and increased plenum volume. This should help with the small T7 throttle body. But more on that later.

While the Viggen is apart all the bits that make a Top Mount GT kit are there on my garage floor at home (no room at the workshop) We are assembling all the kit components to be able to offer this. It will be a complete kit of all the hardware, add downpipe, Turbo and manifold.

New Fuel pump for the Viggen / Drag car pics

Trying to get more than the previous 511whp out of the viggen will require more fuel than the 255hp Walbro will do. The 1000cc Injecotor dynamics were maxed and draining the rail feeding the e85 before.

Trying to get more than the previous 511whp out of the viggen will require more fuel than the 255hp Walbro will do. The 1000cc Injecotor dynamics were maxed and draining the rail feeding the e85 before.

The plan is with more fuel then we can use the GM maf and hopefully have a bit more headroom in T7 to throw a bit more boost at it. There is still quite a bit left in the the 3076.86 If not then the GTX3076 With a Tial Stainless housing and Tial MVS gate should do. Have the manifold and gate parts off the drag car.

Then there comes fitting my new CNC head and manifold to the T7 car. 🙂 But then it needs more flow through the throttle body. Think I have a solution there. That will have to come down the road. Have to finish the drag car up. It is Race Season already!

UPDATE: Ripped the head off the Viggen last night at home. Didn’t have a way to drain the coolant though. Time to see what the New CNC ported head does and make a new intake manifold. Can cut that this weekend. Then theres the drag car, the new Billet Precision 6262 doesn’t quite clear the hood, thats a good problem.. 😉

New clutch for 9-3ss 4cyl

Finally replacing the spec in my SS with a new larger capacity and nicer clutch is quite a relief. The spec has been nothing but trouble since new with no support even pulled it apart once to swap the 30k mile original hydraulics. Now spec says they don’t sell those! No help with the $900 I have invested in the pos. It has maybe 3000 miles on it as a grocerygetter.

Finally replacing the spec in my SS with a new larger capacity and nicer clutch is quite a relief. The spec has been nothing but trouble since new with no support even pulled it apart once to swap the 30k mile original hydraulics. Now spec says they don’t sell those! No help with the $900 I have invested in the pos. It has maybe 3000 miles on it as a grocerygetter.

New clutch is 10mm larger. Same or slightly less pedal pressure. The organic material makes engagement smooth. Back to a dual mass flywheel to keep the f40 quiet.

This along with the new Quaife should give the 245 tires a chance. Time to turn the power up and see where the pistons reach with careful tuning on corn.

Anybody want to buy a used clutch and flywheel?

Now I remember the reason for hating the 18t6cm…

After an afternoon tuning on the -94 2.0 900SE fitted with 18t6cm I am quite disappointed. Got it up there in power but the little guy just wont flow to make the power curve how i want. Initially we fitted a set of spare 42lb Green Giants. On the second pull working up in boost we maxed them out. Swapped for a set of used 630s got enough fuel flowing. Still had the same turbine chose issue as before. Wont make the horsepower. This is on the ragged edge of knock. So the safe place is about 10hp down. Still better than the 270 we managed with 15t6cm on it before. Going to need a GT30 or maybe one of the smaller Billet precisions to be nice enough to call my hotrod. 😉 I am going to try one more trick before it comes off the dyno. Swap to B202 camshafts, this will add some duration. Cant see it helping the turbine choke but I like to know for certain. More pics in the gallery

After an afternoon tuning on the -94 2.0 900SE fitted with 18t6cm I am quite disappointed. Got it up there in power but the little guy just wont flow to make the power curve how i want. Initially we fitted a set of spare 42lb Green Giants. On the second pull working up in boost we maxed them out. Swapped for a set of used 630s got enough fuel flowing. Still had the same turbine chose issue as before. Wont make the horsepower. This is on the ragged edge of knock. So the safe place is about 10hp down. Still better than the 270 we managed with 15t6cm on it before. Going to need a GT30 or maybe one of the smaller Billet precisions to be nice enough to call my hotrod. 😉 I am going to try one more trick before it comes off the dyno. Swap to B202 camshafts, this will add some duration. Cant see it helping the turbine choke but I like to know for certain. More pics in the gallery

2.3i Head/Manifold Dyno results

Filed under: 2.3i Project Car, CNC / R&D Parts, Dyno

Nothing magical as expected but certainly more gains. The red run there is our previous best w retimed stock cams, turbo inlet manifold, tuned length intake, viggen rear muffler and header. The blue there was 252 cams out of a B202 and 70mm throttle body, gains split about 50/50 on those two.

Nothing magical as expected but certainly more gains. The red run there is our previous best w retimed stock cams, turbo inlet manifold, tuned length intake, viggen rear muffler and header. The blue there was 252 cams out of a B202 and 70mm throttle body, gains split about 50/50 on those two.

I still have to extend my fuel maps past 62oo so thats hurting us a bit there. All in all thats a 35whp gain over previous best! Now its time for a larger header as this one was optimized for the motronic setup. Either way the drag car is going to love this setup!

UPDATE: Found a little more in it. 155.9 Tq and HP. something magical there and had to leave it. Quite noticeable gains on the road too. Even threw up a youtube video. Not great, I was occupied with trying to wring every last bit of torque from this beast. You can see how we have made the torque further out every time this is where the Horsepower comes from. It seems insignifigant the 155 peak but it is when you overlay this with the stock it becomes apparent how much we have gained. Just a bit at a time with each part. No cheating and just cranking the boost up to make torque here.

UPDATE: Found a little more in it. 155.9 Tq and HP. something magical there and had to leave it. Quite noticeable gains on the road too. Even threw up a youtube video. Not great, I was occupied with trying to wring every last bit of torque from this beast. You can see how we have made the torque further out every time this is where the Horsepower comes from. It seems insignifigant the 155 peak but it is when you overlay this with the stock it becomes apparent how much we have gained. Just a bit at a time with each part. No cheating and just cranking the boost up to make torque here.

CNC Manifold Ready to go…

With the larger ports in the head we needed matching intake. Using the stock plenum for now to keep the variables down for testing this is what the guys snuck in during production today. I ripped the head off tonight and will have the modified head on tomorrow and hopefully spinning the rollers after lunch. Needs some final matching on the runner to manifold and some fuel rail brackets welded. Best part is that it all went pretty quick so if it makes power it wont break the bank for the hotrods out there. More pics in the gallery. This should help open up the topend on the drag car for the new big turbo…as if 670whp was not enough 🙂

With the larger ports in the head we needed matching intake. Using the stock plenum for now to keep the variables down for testing this is what the guys snuck in during production today. I ripped the head off tonight and will have the modified head on tomorrow and hopefully spinning the rollers after lunch. Needs some final matching on the runner to manifold and some fuel rail brackets welded. Best part is that it all went pretty quick so if it makes power it wont break the bank for the hotrods out there. More pics in the gallery. This should help open up the topend on the drag car for the new big turbo…as if 670whp was not enough 🙂

C900 8v CIS Injection Lines, Interest?

Working with Goodridge for some custom injection lines we have come up with this solution. Available in all the Hose colors. Plastic covered for abrasion protection. Anyone out there looking for lines? Or am I just wasting time and move on to the new saabs?

Working with Goodridge for some custom injection lines we have come up with this solution. Available in all the Hose colors. Plastic covered for abrasion protection. Anyone out there looking for lines? Or am I just wasting time and move on to the new saabs?

To adress other questions. Yes they will be a perfect fit set. There are banjo bolt ends available for the original Cis cars. 😉

Pricing will be based on 2 Quantities. 5-9 sets and 10+ $49 /line or $45. That makes set price $198 for 5-9 or $182 if 10 or more sets.

Update July6: They are in the GS catalog for ordering standard 8-v lines. This will allow us to build each set custom colors etc for that order. Lead time should be about 1-2weeks from a valid order. As always we will only charge when they ship, not before. For you overseas customers the shipping will be list rates. We pass along the best discounts we can negotiate on the freight. Now if you need an exact quote shoot an email to my shipping dept.

Final Update Oct 20th As with all saab projects… There is 2 Saabs in France that have new CIs lines..

2.3i Dyno Results Day1

So played on and off today with the NA on the dyno. First baselined it a few runs. This setup is dead repeatable.

So played on and off today with the NA on the dyno. First baselined it a few runs. This setup is dead repeatable.

After that fitted my 70mm Throttle body. (Robbed it off the drag car) 5 min swap with coolant deleted. Picked up a good 5whp across the board! Then fitted the B202 86-90 camshafts to the same timing as before. Lost all we gained. So then set off on a fishing expedition with cam timing. Swapped it a few times, You can see we ended in the mid 30s for dyno runs!

So all in all 145 whp is quite a ways in on the 2.3i but with the short 4.45 gears and the instant response the extra 10-20 whp up top should make it a blast to drive. Very excited to see how the new head helps. Might even try a sports exhaust instead of this vig original.

CNC ported Cylinder head and Inlet manifold

Just a small bit of a new project for the drag car. Initially the first parts will be T7 and going on my 2.3i NA car for testing. With the CNC the price should be kept reasonable if we can do enough. Once we get some rough data will fine tune them on the flow bench. Using stock intake plenum with new runners. This was needed to eliminate extra variables. For the drag car we will most likely end up with a larger plenum and relocated throttle body. I have some ideas but will have to see what the data says.

Just a small bit of a new project for the drag car. Initially the first parts will be T7 and going on my 2.3i NA car for testing. With the CNC the price should be kept reasonable if we can do enough. Once we get some rough data will fine tune them on the flow bench. Using stock intake plenum with new runners. This was needed to eliminate extra variables. For the drag car we will most likely end up with a larger plenum and relocated throttle body. I have some ideas but will have to see what the data says.

O-ring seals and geometry checks out good. No odd gaskets to deal with just a standard o-ring. For the t5 cars will add coolant temp sensor and extra water passage seals.

O-ring seals and geometry checks out good. No odd gaskets to deal with just a standard o-ring. For the t5 cars will add coolant temp sensor and extra water passage seals.

This ones a little “get it done NOW” rather than pretty. Just trying to prove the project at this stage. Stock injector placement in this version.

This ones a little “get it done NOW” rather than pretty. Just trying to prove the project at this stage. Stock injector placement in this version.

The ports still have to be hand finished at this stage. Certainly removes a bunch of time doing it with the machine. Also makes sure that the ports are close to the same profile.

Headed to the dyno this afternoon. Also have a friend with a flowbench that owes me. But it is a couple hours away. 😉

Headed to the dyno this afternoon. Also have a friend with a flowbench that owes me. But it is a couple hours away. 😉

Quick Youtube HD video up.

2.3i Updates

Since we have some parts to be tested on the 2.3NA 900 it was time for some updates. Upgraded to Hydraulic clutch out of a parts car, B205R clutch a used Alu flywheel and custom gearbox. The gearbox is a 4.45 final with the taller 5th. So it still cruises decent on the highway. The gearbox is built of scrap parts. 🙂 The ring gear is the early 94/95 style that uses the expensive Quaife so it is still open. Even got a bit larger camshafts out of a B202.

Since we have some parts to be tested on the 2.3NA 900 it was time for some updates. Upgraded to Hydraulic clutch out of a parts car, B205R clutch a used Alu flywheel and custom gearbox. The gearbox is a 4.45 final with the taller 5th. So it still cruises decent on the highway. The gearbox is built of scrap parts. 🙂 The ring gear is the early 94/95 style that uses the expensive Quaife so it is still open. Even got a bit larger camshafts out of a B202.

The main reason for all this is some Cylinder head Modifications. More on that soon. Weather is in the 60s to day so will have some data this evening.

Clutch Selection NG900/9-3

This should help with clutch selection. This is just a guide based on my actual experiences. Ultimate life will depend on driving style, boost regulation and breakin given. Should at least help most with clutch selection. This is one place where overkill is not always the best idea. Certainly not an absolute but way closer than the baloney from another clutch MFG, I’ll post those emails sometime.

This applies to Stock Viggen pressure plate and Viggen disk or VIG plate and my custom disks by clutchnet. The Twin is my Quartermaster 7.25″ two disk. race setup like in the red vig and drag car. Just a bit of background on the capacity methodology. One example is the Stg1 combo, We tested this to 400Ftlbs @wheel with no slip so gave it a rating of 350 at wheels.

Stock Pressure plate (This includes Spec blue painted stock ones) should not be run past 7000rpm EVER, That means 6800 max since there is a 200 cushion in trionic. The plate deflects considerably. Running them over this is a great safety risk. We experienced multiple dowel pin failure and plate explosion on the drag car as we found this out. Cost a few gearboxes, flywheels etc…

Some of the broken junk… Scratch that, call it Experience.. Yeah thats what it is.. 🙁 http://genuinesaab.com/gallery/clutchtemp

Manifold Fab / Welding

Since we have been doing more fab work for the local tuner shops Figured it was time to show off some. I usually don’t take pics of those but here is one of my manifolds that Adam just finished up. Two passes and fully purged. Perfectly clean inside to protect that expensive turbo. Welded to a 1/2″ Steel flange that is bolted to a 1″ plate for perfect sealing. You can click through there for a 1200px version.

Since we have been doing more fab work for the local tuner shops Figured it was time to show off some. I usually don’t take pics of those but here is one of my manifolds that Adam just finished up. Two passes and fully purged. Perfectly clean inside to protect that expensive turbo. Welded to a 1/2″ Steel flange that is bolted to a 1″ plate for perfect sealing. You can click through there for a 1200px version.

In that last photo you can notice its the guy that owns another dyno in town and builds racecars. He wanted Adam to weld his personal car! When the competition brings their work here thats a nice compliment. Thanks Sam!

Ultimate Viggen daily? 350Ftlbs and 390whp

With the idea of keeping the torque reasonable to protect the drivetrain and make it a monster still this is where I ended up. The car would easily make 400Ftlbs at the wheel on a flat 20psi. Safe but past what the street tires would hold. With the flat torque the car just pulls harder and harder as the HP builds. Making quite a sneaky fast car. Without the torque peak of a stock turbo or the 18t. Also the low ~16psi boost at 100f air temps will help the car to perform in the desert. The horspower is ending up around 385/390 at the wheels! All keeping peak boost under 20Psi. Something that will make power all day long without worry. The 750CC injectors have plenty of extra margin. The manifold helps the high rpm flow without the need to run larger kams and kill the fuel mileage. There are a few tricks here and there in the hardware. One interesting thing, this is all through a BSR catback and stock airbox/ filter. With a vert keeping the noise down is important in a daily driver these certainly help. This one sounds like a jet at full power. More videos from the road this weekend. Here was a quick teaser video. Another Top Mount Viggen Teaser Now to fine tune the TQ limiters so we can protect 1/2 then work on the gas mapping.

With the idea of keeping the torque reasonable to protect the drivetrain and make it a monster still this is where I ended up. The car would easily make 400Ftlbs at the wheel on a flat 20psi. Safe but past what the street tires would hold. With the flat torque the car just pulls harder and harder as the HP builds. Making quite a sneaky fast car. Without the torque peak of a stock turbo or the 18t. Also the low ~16psi boost at 100f air temps will help the car to perform in the desert. The horspower is ending up around 385/390 at the wheels! All keeping peak boost under 20Psi. Something that will make power all day long without worry. The 750CC injectors have plenty of extra margin. The manifold helps the high rpm flow without the need to run larger kams and kill the fuel mileage. There are a few tricks here and there in the hardware. One interesting thing, this is all through a BSR catback and stock airbox/ filter. With a vert keeping the noise down is important in a daily driver these certainly help. This one sounds like a jet at full power. More videos from the road this weekend. Here was a quick teaser video. Another Top Mount Viggen Teaser Now to fine tune the TQ limiters so we can protect 1/2 then work on the gas mapping.