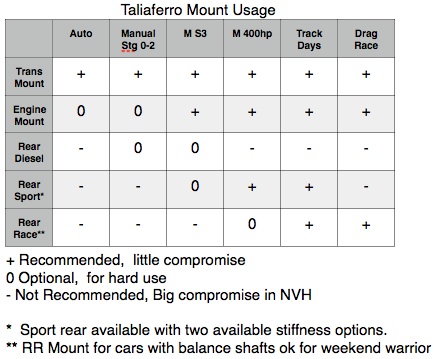

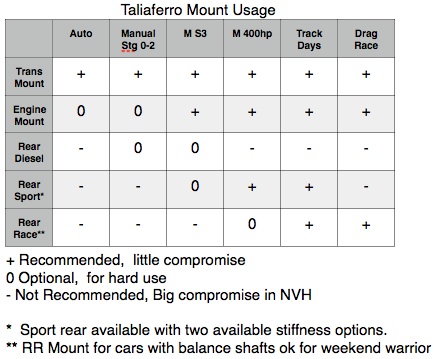

With all the mounts options for the many applications from street stock to drag racing it wa time to work up a matrix based on experience of what works where. Hopefully this helps you get the right mounts for the best experience possible.

With all the mounts options for the many applications from street stock to drag racing it wa time to work up a matrix based on experience of what works where. Hopefully this helps you get the right mounts for the best experience possible.

Since the gearbox needed to come out of the 9-3SS to upgrade the clutch it was time to fit the Quiafe LSD. This is interesting since there is no service info from Gm US, Saab or GM europe. Mainly needed bearing preload info. Just set it to the same as it was on disassembly. Also since there is no spare parts I had to leave the the crunchy second gear syncro. Thanks GM..

Since the gearbox needed to come out of the 9-3SS to upgrade the clutch it was time to fit the Quiafe LSD. This is interesting since there is no service info from Gm US, Saab or GM europe. Mainly needed bearing preload info. Just set it to the same as it was on disassembly. Also since there is no spare parts I had to leave the the crunchy second gear syncro. Thanks GM..

The clutch was the original full spec upgrade that never worked right and was certainly not worth the money invested. Most of it was the complete randomness from the self adjust pressure plate. Sorting my own setup now from proper factory parts.

Also while the subframe and downpipe are out the time is here to fabricate a manifold and fit the gt3071 turbo so we can make some real power! More on that later.

So the much abused and neglected 2.3i project car got some attention. Mostly a dyno mule, but we need to put more miles safely on the road this year. Fitted airbags and washer system to get it road worthy. This one with the fast steering and tuned motor is a blast to drive. My favorite lunch or mountain bike car.

While Dusty was in swapping the dash we added a Turbo instrument assy to go along with the t5 swap. Unfortunately even though the Shift up and CE light are wired the Turbo gauge is not. We had to add 2 wires from the Bulkhead connector to the instrument. Signal from T5 and signal Ground from body. Now we have a Turbo gauge that never reads boost.. 🙂 We might even wash it! Have to get it ready for the next project. Will be intake related and apply to the Turbos as well.

Another Black Viggen with a Top mount turbo fired up today.. With stock wheels it looks factory. Dropped on the Koni Kit is the only sign. The exhaust is even quiet, making a great sleeper, ( as much as you can hide a Viggen!) This one is Gt2871 on a tubular manifold with 3in downpipe to Simons Catback. It is a Flex Fuel Setup with 750cc injectors and Walbro 255, t5 cams. Nothing crazy just a great daily driver. Upgraded from stg4 18t6cm. Here are a couple pics. Will post some more when it is finished. After some miles on low revs/boost for breakin will tune it on the dyno.

Just a rough first prototype. I know there are a bunch excited about this part. Also shown is a close version of the new shift knob. Will also be available in a few thread sizes so you can run whatever knob you want. Mention the threads you want in the comments.

Just a rough first prototype. I know there are a bunch excited about this part. Also shown is a close version of the new shift knob. Will also be available in a few thread sizes so you can run whatever knob you want. Mention the threads you want in the comments.  The top of the rev lockout will be more rounded. Compatible with stock shift boot. Will sort out the little details first in a test car then get these headed to production in a few weeks.

The top of the rev lockout will be more rounded. Compatible with stock shift boot. Will sort out the little details first in a test car then get these headed to production in a few weeks.

From the recent Saab accessory sale picked up these 17s real cheap. Fitted some old takeoff 215-45 P-Zero Neros. Saving for some 235s in the spring. These are a bit small. The shorter tires further help acceleration and brake. Had to fit a -99 brake hose without the extra venturi booster to take away a little brake assist, they were a bit too much in the city. Most likely these will get the race tires, fair bit lighter than the CH. But hey my Chs are all still true. Cant say the same for the lightweight OZs.

Plenty of clearance without spacers even for the 330mm AP.

This is the first fluid I have found to be better than the stock 0063.

This is the first fluid I have found to be better than the stock 0063.

In the cold it is noticeably better. Will see what it does for the F40s crunchiness. Interesting to see how the first gear on the drag car looks after a few passes. They tend to take quite a beating putting down over 6000lbs on the launch.

Cheaper too! http://www.redlineoil.com/product.aspx?pid=140&pcid=7

Not to be confused with their thick blue that is aggressive to the syncros and with that fluid I have witnessed a couple early syncro failures in customer gearboxes.

Anybody else running this?

Sorting out the 9-3/900 clutch lines and wondering if anyone wanted another color besides Clear or the Deep Blue we use on the rear 300mm kit. Only a couple days. Goodridge has some neat colors. More on the hose post: New Clutch parts Update: Red Blue and clear it is…

http://www.importfaceoff.net/race_rules.htm#FWD The new schedule will be up later in the year.

There is also a 67mm inducer turbo limit for true street. This is the class we are working towards. Outlaw street is 72mm

Working around the fact that under 1/4 of the shifter cores are returned we had to work out a better solution. A core is just borrow, not for keeps. A little aspect most miss and causes lots of delays waiting on a certain core part number to return for the next guy in line.

Working around the fact that under 1/4 of the shifter cores are returned we had to work out a better solution. A core is just borrow, not for keeps. A little aspect most miss and causes lots of delays waiting on a certain core part number to return for the next guy in line.

The solution was to build a full new shifter from scratch. They will be the same function as what we currently have but will require end user to enlarge the hole in the base of the shifter and assemble it at their end. No big deal for always available and no core return, especially for our overseas customers. The shafts are made of the same metric dimensioned materials as factory. The premium version will have a billet aluminum lockout mechanism and threaded top to accept aftermarket shift knobs! These should be available starting next week.

Fitted the 1000cc Injector Dynamics nozzles from the drag car in my Viggen to help get a bit more fuel up top that was not there with the 750cc, the results we interesting. Yeah that graph is 511whp. 😉

Fitted the 1000cc Injector Dynamics nozzles from the drag car in my Viggen to help get a bit more fuel up top that was not there with the 750cc, the results we interesting. Yeah that graph is 511whp. 😉

Initially we were down on power ~470s , mostly a function of the gear ratio change. No big deal, within a few percent. Some a function of Ethanol composition compared to summer fuel and the rest to my temp corrections being a big off in T7 calibration. Now the issue is we are up against the MAF calculation limit in T7. Way past the traction limit anyway. Tomorrow will start working down in power to get the rest of the maps sorted out. Pulled a little boost out the last run to keep the gearbox and clutch happy. Fuel pump is done by 5000. Not really wanting to fit -6 line and second pump. Might make two pumps in the tank and see how that goes. .

Some pretty major updates to the viggen power and handling over the weekend.

Some pretty major updates to the viggen power and handling over the weekend.

Installed the new solid strut mounts Friday evening. With the new design mount found an inch or so more compression travel and fitted 75lb stiffer springs. After making larger steps on rates now I am trying to find the sweet spot. Always a balance front and rear, I seem to get stuck at what if…

Read on for the rest of the details. Read the rest of this entry »

Now that we are done with the big CNC job we can get working on some new projects. One of the first in line was an upgraded strut mount for the 9-3 and eventually the Ng900 for use with 2-1/2″ coil springs. Just trying to get some proof of concept parts in cars to rack up miles. The cold weather and Race valved konis should give them a beating. For now they are stock geometry but may make them with ideal geometry for specific uses. Always hated the adjustable ones that slipped.

Machined aluminum with a Teflon lined bearing so they should stay quiet for a while. Cheaply rebuildable and use the stock strut rotational bearing. Base is setup for a 2-1/2″ Coil-over only, not for stock springs. The bolts are even replaceable if one gets messed up, unlike the stock studs. Couple other features that should make for cheap coilover kits.

Should have them in my viggen tomorrow night.

BBs CH 18s on My Viggen. Nice dark wallpaper in 1920×1200 Should be plenty for most. If you need a different size let me know. Comments welcome.

This first one will most likely will end up in my Viggen. Now that the drag car uses Vig axles I can have one spare for both cars.

This first one will most likely will end up in my Viggen. Now that the drag car uses Vig axles I can have one spare for both cars.

The lower gears. 4.45 compared to stock 4.05 should help it jump a bit better. Get to third pulling earlier too. Now to leave the short 5th too. And let it wind on the highway or go back to tall 5th and live with it…

< Stock gear ratio

< Stock gear ratio  < 4.45 Gears

< 4.45 Gears

Now given that info and data from the latest dynorun (July 17 3076 r2) Gives us ground torque. Also known as thrust at the tire patch. One oversight in this chart is overlooking the necessary limiters in first gear and a bit in second. If only it would hook that 6000lbs of thrust.. That would give nearly 2g of acceleration! Ill keep the limiters.

DATA: 4.05 Tq and the 4.45 See how given the same engine power the shorter 4.45 makes more output torque. This is where the “pull” comes from in swapping gears. Same would apply when messing with tire diameter. Or it allows less input through the gearbox to make the same on the ground, always a good thing.

Found this on the server. Still applies 100% today.

| Info To: All Customers, Dealers and Upgrade Technicians From: N. Taliaferro Date: 04/10/03 , updated 08/13/03 Re: Upgrade Pre-Installation Procedures. Install Requirements |

Needing more precise control over the twin disk clutches the logical solution was to swap to a Braided hose. There is no comercial adaptor available that I could find so decided to make them. I ran a few adaptors for the clutch lines on the CNC Lathe yesterday. Not final, Just a prototype with closest available hose parts. Price is nice too not starting with the factory hose like the 9000 parts. Looking like about Thanksgiving time there will be enough free time on the CNC Mills to run some new project parts. That will be surely exciting.

Needing more precise control over the twin disk clutches the logical solution was to swap to a Braided hose. There is no comercial adaptor available that I could find so decided to make them. I ran a few adaptors for the clutch lines on the CNC Lathe yesterday. Not final, Just a prototype with closest available hose parts. Price is nice too not starting with the factory hose like the 9000 parts. Looking like about Thanksgiving time there will be enough free time on the CNC Mills to run some new project parts. That will be surely exciting.

My 1978 99 racecar. 16v turbo w 4speed and 1990 S/R suspension. This was my first “air clutch” car. Had airbags in the rear,l Delrin suspension bushings and lots of other one-off parts. Been stored inside for the last 10 years. That bumper sticker where the plate goes got me out of a couple tickets. 😉

With the new 8gal fuel tank built and installled now it’s time to work on the wheel bearings and finish the airbags.

Once that’s done it really needs turbo. If only for the sound. Have to look at the numbers some more but thinking two gt12s or so. 🙂 then vw gearbox. If anyone knows details on that swap let me know. I know the adaptor will be easy.

Like this:

nova on my Dyno a few times. Love when the turbos fight back and forth on the bov.

I have some sketches of a long runner manifold to make hopefully have time this winter. Then it gets efi. Sick of the carb can’t break 40mpg with the distributor/carb combo. Sure there is someone that can work magic on the springs/weights but I can’t.

Plan is to drive the ugly beast to SOC2011 no small feat.

Hopefully headed this way soon.

Couple samples of the Smoke Clear powdercoat. Adds visual depth to the engraving. Will also eliminate corrosion etc. Just over Machined finish on these Aluminum oil caps. We could do this on any of the parts special order.

No doubt we have more torque and traction than in the past at this point. Friday night first pass! Going to upgrade to Viggen axles at this point and probably change gearing too. This will both lower the input axle torque and raise the margins. Hope this works. Buggered the inner drive a bit also. The outer is a bit crunchy so it may have internal damage. Hoping the two massive overrevs are not too damaging to the rotating assembly. Not touching valves at this point so crossing fingers. More drag car axle carnage VIDEO You can see the sparks from the axle at the end.

No doubt we have more torque and traction than in the past at this point. Friday night first pass! Going to upgrade to Viggen axles at this point and probably change gearing too. This will both lower the input axle torque and raise the margins. Hope this works. Buggered the inner drive a bit also. The outer is a bit crunchy so it may have internal damage. Hoping the two massive overrevs are not too damaging to the rotating assembly. Not touching valves at this point so crossing fingers. More drag car axle carnage VIDEO You can see the sparks from the axle at the end.

Here is a current underside shot. You can see the spherical bearings in the suspension, Wastegate dump tube and downpipe. Std 6-point and not a lot of other special parts. Might run a batch of the spherical bearings if there is demand.

Here is a current underside shot. You can see the spherical bearings in the suspension, Wastegate dump tube and downpipe. Std 6-point and not a lot of other special parts. Might run a batch of the spherical bearings if there is demand.

Steven got my old Corbeau seat mounted on a stock base. Only saved 12lbs but accommodates My 6’2″ and stevens foot or so less. 😉

Steven got my old Corbeau seat mounted on a stock base. Only saved 12lbs but accommodates My 6’2″ and stevens foot or so less. 😉

Fully ducted the intercooler to the bumper opening. Never got to try this out with the axle breakage. They whipped this up in an hour out of thin aluminum sheet. Should have a decent effect on big end power. Looks nicer too.

Found the limit of the axle! Mo-Kan had some BA track prep going on!!!

Iphone locked up after that but you get the idea. The car barely rolled.

http://www.youtube.com/watch?v=cRRn1pfwgDQ

Axles out of a 40k 2000 9-3 Hot. Lasted 2 years. Will go back with another for now. Glad it was on the line, that would have been an experience at speed with the axle flopping.

Will get out the macro for some grain shots of the failure when it is pulled out.

Popped a wastegate hose off while busting on the dyno to get to the track friday night. So there is certainly a bit left in the turbo. Not so much with the fuel. Definitely a OhSh*$ moment! The map sensors will need upgraded to run this much. ![]() Target was the same power as the previous graphs. Just with less china junk and more Made in America! Tial Mv-s Cute little bugger. Might upgrade the Bov too. Not sure. Picked up a Previous gen Tial blowoff.

Target was the same power as the previous graphs. Just with less china junk and more Made in America! Tial Mv-s Cute little bugger. Might upgrade the Bov too. Not sure. Picked up a Previous gen Tial blowoff.

Starting to look nicer too. You can see some room has been made for the next step.

Sure will do a heck of a burnout and stage. ![]() Made it home around 2 am.

Made it home around 2 am.